UK designer and manufacturer GJD, which makes external perimeter protection and intruder detection equipment, has announced investment into a new product.

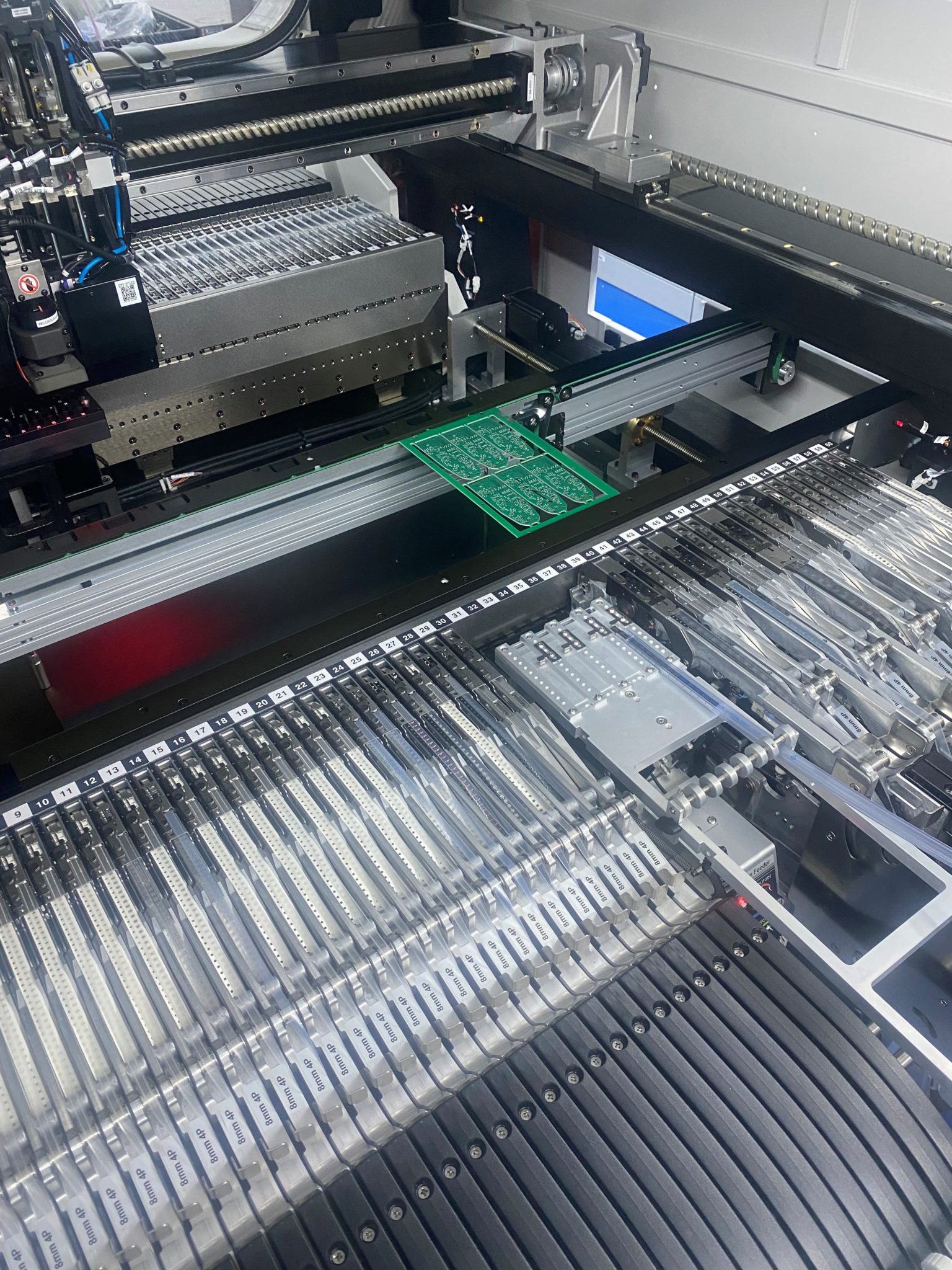

The new Hanwha Techwin SM482 Plus Surface Mount Technology (SMT) machine allows high-speed automation during the electronic assembly process.

But the company claims it can drive efficiency and lessen GJD’s carbon footprint.

Mark Topp, Operations Manager at GJD, said: “Our investment in state-of-the-art SMT technology is a real gamechanger for our business.

“The equipment significantly decreases our carbon footprint and aligns with our wider commitment to being a responsible and sustainable manufacturer in the security industry.

“We are able to provide reliable continuity of supply to our customers and establish ourselves as a truly ‘Made in Britain’ brand.”

Having previously outsourced some of the SMT assembly, GJD will now be able to complete the manufacture of its products in-house and thereby significantly decrease the business’ carbon footprint, whilst increasing UK employment opportunities.

The new machine also provides GJD with greater flexibility to manufacture, stock and supply its products in small batches, thus allowing the business to expedite its customers orders on time and in full.

With nearly 40 years of experience in the security industry, GJD is an award-winning UK manufacturer, designer and supplier of professional external detector equipment, LED illuminators, lighting controllers and ANPR cameras.

GJD is a proud recipient of the Queen’s Award for Enterprise in International Trade and has also achieved many other security industry awards including the BSIA’s contribution to exporting.

Based in Heywood, Greater Manchester, GJD has extensive knowledge and expertise, with over 32 years of experience in the security industry.

Managing Director, Mark Tibbenham commented: “We take great pride in developing new innovative designs; utilising the latest technology and implementing state-of-the art manufacturing techniques, which will ensure our respected position within the industry.”

Surface-mount technology was developed in the 1960s. By 1986 surface mounted components accounted for 10% of the market at most, but was rapidly gaining popularity.

By the late 1990s, the great majority of high-tech electronic printed circuit assemblies were dominated by surface mount devices. Much of the pioneering work in this technology was done by IBM.